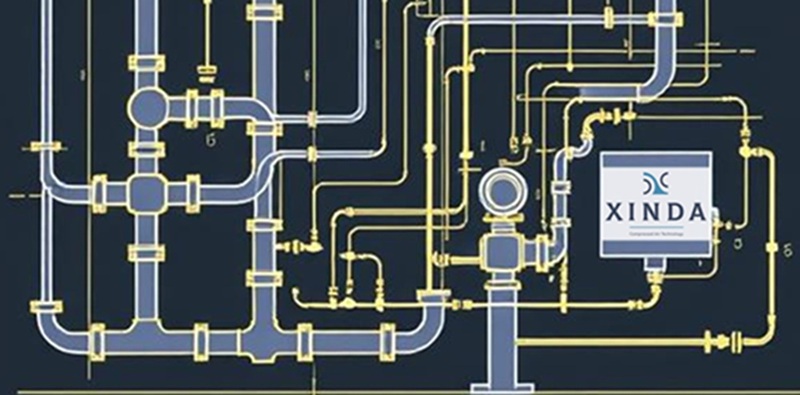

Best Practices for Piping Design in Compressed Air Distribution

A well-designed piping system is essential for delivering clean, consistent, and efficient compressed air.

Poor layout or materials can cause pressure drops, leaks, and energy waste — costing you performance and money.

Follow these best practices for optimal results:

1. Choose the right material

Use corrosion-resistant piping such as aluminium or stainless steel. Avoid materials like galvanized steel that can cause rust and contamination.

2. Keep the layout efficient

Design a loop system instead of long, straight branches. This ensures even air pressure throughout your facility and allows for future expansion.

3. Size it correctly

Undersized pipes increase friction and pressure drop. Select pipe diameters that match your air demand and flow rate.

4. Minimize bends and restrictions

Every elbow or fitting adds resistance. Keep runs short and smooth to maintain pressure and reduce energy loss.

5. Plan for drainage and condensate removal

Install sloped piping and automatic drains to prevent water build-up that can damage tools and equipment.

6. Include isolation valves and drop points

These allow for easy maintenance and flexible connection of new equipment without shutting down the entire system.

💡Good piping design = Reliable performance, lower energy costs, and cleaner air quality.

Investing in proper layout and materials pays off in efficiency and longevity.