Energy-Efficient Compressor Technologies: VSD vs Fixed Speed

- Fixed-Speed Compressors

- How they work:

A fixed-speed compressor runs at one constant motor speed. When air demand is reached, it loads (compresses) air. When demand is met, it unloads or stops.

Pros:

- Simpler design, lower upfront cost.

- Robust and reliable for steady, predictable air demand.

- Easier maintenance due to less complex electronics.

Cons:

- Less efficient when air demand fluctuates.

- Consumes energy even in “unloaded” mode (idling can waste 20–30% of power).

- Higher overall lifecycle cost if usage varies a lot.

- VSD (Variable Speed Drive) Compressors

- How they work:

A VSD compressor adjusts the motor speed to match real-time air demand. If demand is low, the motor slows; if demand rises, the motor speeds up.

Pros:

- Significant energy savings (can reduce consumption by 35–50% compared to fixed speed).

- Soft start reduces electrical stress, improving motor and component life.

- Tighter pressure control, reducing pressure band and system leaks.

- Ideal for applications with fluctuating or unpredictable air demand.

Cons:

- Higher upfront investment.

- More complex design → requires skilled servicing and quality power supply.

- In very stable demand situations, savings may not justify cost.

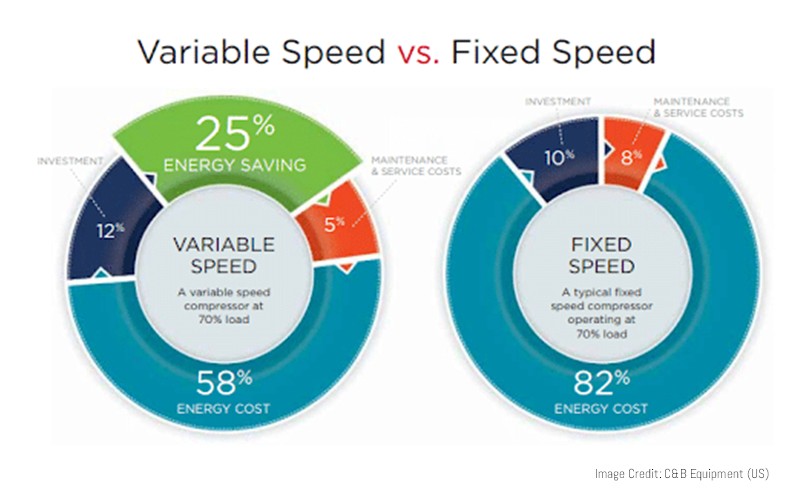

- Energy Efficiency Comparison

- Fixed-Speed: Best for consistent, 24/7 operations where air demand barely changes. Efficiency is lower when running part-load.

- VSD: Best for variable demand environments—saves electricity by matching supply to demand. Over time, energy savings often offset the higher purchase cost.

Quick Analogy

Think of it like driving a car:

- Fixed Speed Compressor = pressing the accelerator fully and using the brake when you don’t need speed.

- VSD Compressor = using cruise control that automatically adjusts your speed to match road conditions—saving fuel (energy).