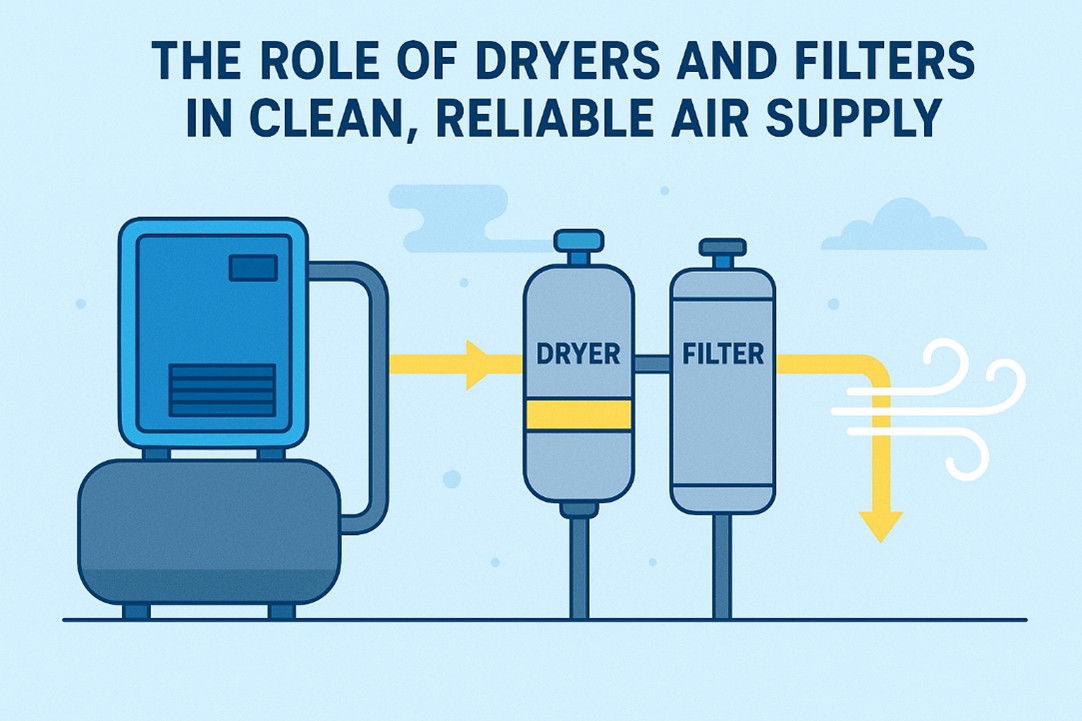

How dryers and filters play a critical role in delivering clean, reliable air supply:

Compressed air is only as good as the quality of the air delivered. Without proper treatment, moisture, oil, and particulate contaminants can compromise productivity, damage equipment, and risk product quality.

Why Dryers and Filters Matter

When air is compressed, its temperature increases and as it cools, moisture naturally condenses. Along with ambient dust and potential oil carryover from lubricated compressors, this creates a cocktail of impurities. If left untreated, these contaminants can cause:

- Corrosion in piping and pneumatic equipment

- Blockages in valves and orifices

- Reduced efficiency of downstream tools and machinery

- Contamination of end products – especially in food, beverage, and pharmaceutical industries

In short, untreated air leads to higher maintenance costs, downtime, and potential regulatory non-compliance.

The Role of Dryers

Dryers remove moisture from compressed air, ensuring it stays dry and reliable. Common types include:

- Refrigerated Dryers – Cool the compressed air to condense and remove moisture. Ideal for general manufacturing and industrial use.

- Desiccant Dryers – Use absorbent materials to achieve very low dew points. Essential for applications requiring ultra-dry air, such as pharmaceuticals or electronics.

- Membrane Dryers – Use selective permeation to remove water vapor, often used in smaller-scale or point-of-use applications.

The right dryer ensures that air meets the specific moisture requirements of your process, protecting equipment and product quality.

The Role of Filters

Filters trap and remove contaminants like dust, oil aerosols, and solid particles. Different stages of filtration are typically used to achieve clean compressed air:

- Particulate Filters – Capture solid particles such as dust, rust, and dirt.

- Coalescing Filters – Remove oil aerosols and fine liquid contaminants.

- Activated Carbon Filters – Eliminate oil vapours and odours for applications demanding the highest air purity.

By combining the right filters, you create a barrier against harmful contaminants, extending equipment life and ensuring consistent performance.

Benefits of Proper Air Treatment

Investing in the right dryers and filters brings measurable benefits:

- Longer equipment lifespan and reduced downtime

- Lower energy and maintenance costs

- Improved end-product quality and compliance with industry standards

- Greater reliability and efficiency in daily operations

Conclusion

Compressed air is vital – but clean compressed air is critical. Dryers and filters are not optional add-ons; they are essential components of a reliable compressed air system. By choosing the right treatment technologies and maintaining them regularly, businesses can protect their investments, enhance efficiency, and deliver products that meet the highest quality standards.